• Classification: typical cycles, heavy duty and aeroderivative designs, applications.

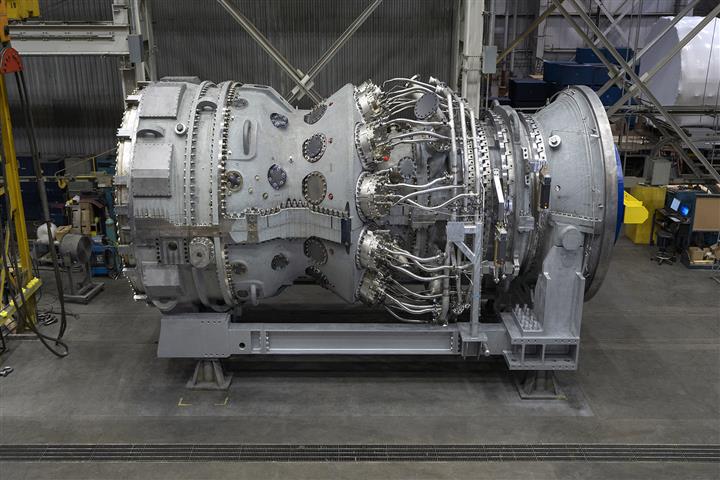

• Presentation: main components. Typical machineries on the market.

• Construction and design: compression, combustion, expansion. Rotor dynamics, coupling.

• Ancillaries equipments: internal cooling, lubrication, control system with typical parallel control loops and firing temperature calculation, speed, combustion, fire detection, gas detection, lube oil mist safety devices. External ancillaries: filtering, exhaust stack, fire fighting, fuel supply.

• Thermodynamics: ideal and actual gas, evolution through compression and expansion, according isentropic and polytropic processing.

• Centrifugal and axial compression. Performance, stability and other limits.

• Combustion: types of combustors, combustion operation. Fuel type influence. Cogeneration process. Low NOx designs.

• Expansion: one shaft or two shafts design expansion operation.

• Performance according to actual atmosphere data, fuel selection. API charts. Available load characteristics: rotation speed, firing temperature, IGV influences. Open cycle, combined cycle examples.

• Selection criteria according availability, operation and maintenance requirements.

• Bidding: significant informations for data sheet writing.

• Start-up and shut-down operation: sequences steps, trip actors.

• Air filtering, lubrication and fuel systems.

• Performance and mechanical operation monitoring.

• Maintenance during operation: compressor cleaning devices.

• Maintenance objectives and planning: operation, load, fuel influences.

comments (0)