• Different types of pumps, applications in the oil and gas field.

• Performance curves of a centrifugal pump: head, efficiency, absorbed power, NPSH.

• Technology of centrifugal pumps, miscellaneous architectures.

• Mechanical seals: different arrangements, related auxiliary systems.

• Operating limits: cavitation, hammer shock, priming issues, case of 2 pumps running together.

• Start-up and operation monitoring: specific case of hot pumps, LPG pumps, vacuum pumps.

• Troubleshooting current failures

• Reciprocating compressors architecture: number of stages, cylinders, overall layout, typical applications.

• Technology of main components, auxiliaries.

• Influence of process conditions on compressor performance: suction or discharge pressure, suction temperature, gas composition. Case of multi-stage compressor.

• Flow control, specific safety devices. Start-up philosophy.

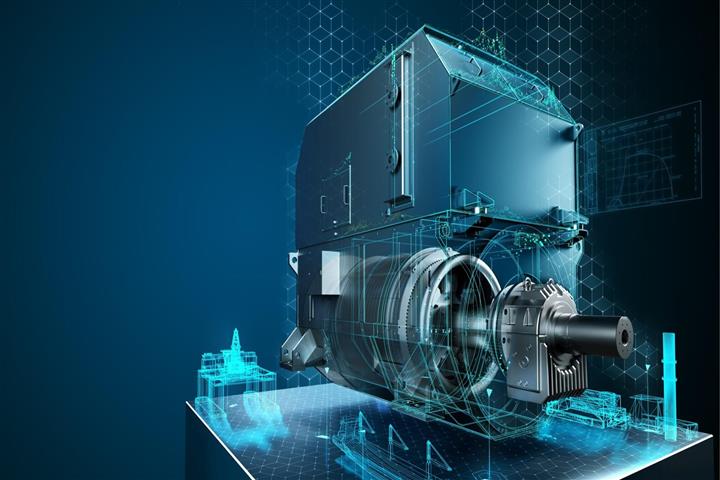

• Description of a multi-stage centrifugal compressor.

• Technology of main components, auxiliaries.

• Pressure increase process for a compressor stage. Performance curves, influence of suction conditions and gas composition.

• Operating window: low and high speed limits, stonewall, surge, typical anti surge protection systems.

• Flow regulation: control valve, speed variation, inlet guide vanes. Specific care for start-up.

• Description of a steam turbine, different families, standard applications.

• Working principle, classification and technology: number of stages, exhaust conditions, expansion process all through the machine.

• Operation: start-up and performance monitoring. Speed control, safety devices.

• Gas turbine design and performance, main types, industrial and aero derivative engines, pressure and temperature profiles along the machine.

• Influence of environmental conditions: temperature, elevation. Impact of suction and exhaust friction losses on turbine performance. De-rating from ISO conditions.

• Efficiency improvement techniques; regenerative cycle, combined cycle, cogeneration, NOx reduction equipment.

• All course is supported by concrete examples based on true industrial applications, and displays of cutaway drawings, pictures or videos of site installed equipment.

comments (0)